The Complete Guide to Custom Molded Rubber: Materials, Methods & Applications

The Complete Guide to Custom Molded Rubber: Materials, Methods & Applications

Blog Article

In today’s demanding industrial landscape, custom molded rubber components are essential for performance, reliability, and precision across countless applications. Whether you're in food processing, pharmaceuticals, fluid handling, or air-operated pump systems, custom rubber parts play a vital role in sealing, isolating vibration, and withstanding harsh operating conditions.

At California Rubber, we specialize in engineering and manufacturing custom molded rubber products that meet exacting industry standards. From Tri Clamp sanitary screen gaskets to AODD valve balls, our expertise ensures your parts are built to perform, no matter how complex or challenging the application.

In this complete guide, we’ll break down the key materials, molding methods, and applications for custom rubber, helping you understand how to make the best choice for your needs.

What Is Custom Molded Rubber?

Custom molded rubber refers to rubber components manufactured to precise specifications using molding processes like compression, transfer, or injection molding. These parts are engineered to solve specific challenges where standard, off-the-shelf rubber products fall short.

Unlike generic rubber components, custom molded rubber parts are designed for:

Exact fit and tolerances

Specific environmental or chemical resistance

Durability under mechanical stress or vibration

Compliance with FDA, USP Class VI, or other regulatory standards

This makes custom rubber vital for industries where performance and safety can’t be compromised.

Popular Materials Used in Custom Molded Rubber

Material selection is the foundation of any high-performance rubber part. Choosing the right rubber compound depends on the application's exposure to temperature, pressure, chemicals, and mechanical forces.

1. EPDM (Ethylene Propylene Diene Monomer)

Excellent resistance to ozone, steam, and weather

Commonly used in sanitary gaskets and HVAC systems

2. Silicone

Withstands extreme temperatures

Biocompatible and FDA-approved for medical and food applications

3. Nitrile (Buna-N)

Great for oil and fuel resistance

Often used in industrial seals and diaphragms

4. Viton® (FKM)

Superior chemical and heat resistance

Ideal for aggressive fluids, often found in AODD valve balls

5. Neoprene

Offers moderate oil and chemical resistance

Common in automotive and marine applications

6. Natural Rubber

Excellent for shock and vibration absorption

Used in isolators, mounts, and some pump components

Each compound can be customized with additives or blended with other materials for enhanced performance characteristics.

Custom Rubber Molding Methods

Custom molded rubber components can be manufactured using several techniques. The selection depends on the complexity, production volume, and material characteristics.

1. Compression Molding

Ideal for low- to medium-volume runs

Best suited for large or thick parts

Cost-effective tooling and minimal waste

2. Transfer Molding

Allows for more complex geometries than compression molding

Useful when inserts (like metal or mesh) are part of the design

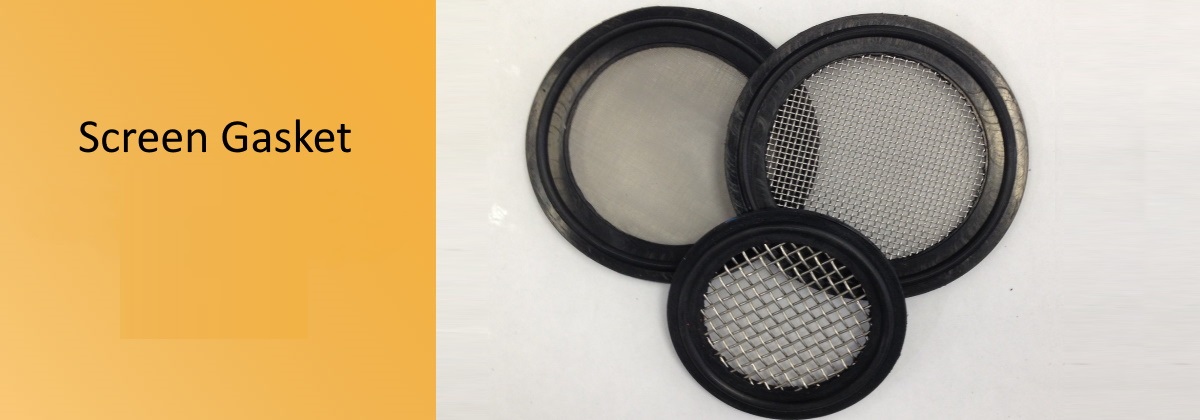

Great for making Tri Clamp sanitary screen gaskets with embedded mesh or perforated screens

3. Injection Molding

High-precision and high-speed process

Excellent for tight-tolerance components

Most efficient for high-volume production

Preferred method for small, intricate parts like AODD valve balls

All these methods support value-added processes such as rubber-to-metal bonding, trimming, and post-curing for enhanced part performance.

Applications of Custom Molded Rubber

Custom rubber components are essential across many industries. Below are key sectors and examples of components where precision rubber makes a difference:

● Food & Beverage Processing

Sanitary gaskets and Tri Clamp sanitary screen gaskets

Must comply with FDA and 3-A standards

Used in hygienic piping systems and CIP (Clean-in-Place) processes

● Pharmaceutical and Biotech

Biocompatible rubber seals, O-rings, and diaphragms

Maintain sterile environments and resist chemical degradation

● AODD Pumps and Fluid Handling

Custom molded AODD valve balls for accurate flow control

Rubber diaphragms, gaskets, and seals for aggressive fluids

● Aerospace and Defense

Rubber isolation mounts and vibration dampeners

Extreme tolerance to heat and pressure

● Automotive

Custom bushings, mounts, and grommets

Designed to resist heat, oil, and wear

● Electronics and Electrical

Grommets, strain reliefs, and EMI shielding rubber parts

Ensure cable protection and system reliability

Why Sanitary Gaskets and Screen Gaskets Matter

In sanitary environments, maintaining a hygienic seal is non-negotiable. Sanitary gaskets and Tri Clamp sanitary screen gaskets ensure that contaminants stay out and product integrity stays in.

Custom molded options allow:

Precision fit to eliminate dead space

Compatibility with CIP/SIP cleaning cycles

Enhanced performance with pressure and temperature fluctuations

Tri Clamp sanitary screen gaskets take this a step further by providing in-line filtration while maintaining a secure seal. Custom rubber molding allows for screen integration with silicone, EPDM, or Viton® compounds, all tailored to your system's needs.

The Role of AODD Valve Balls in Fluid Systems

AODD (Air Operated Double Diaphragm) pumps are workhorses in fluid transfer for chemicals, slurries, and viscous liquids. At the heart of these systems are AODD valve balls, which control the flow direction and ensure pump efficiency.

Custom molded AODD valve balls offer:

Optimized hardness for superior sealing

Resistance to chemical attack

Compatibility with a range of elastomers for various fluids

Precision in shape and weight distribution is crucial for consistent performance, which only custom rubber molding can deliver reliably.

How California Rubber Delivers Superior Custom Molded Parts

At California Rubber, we don’t just make rubber parts—we engineer performance solutions.

Here’s how we add value:

Material expertise: We help you select the best compound for your application

In-house tooling: Rapid prototyping and cost-effective mold creation

Bonded solutions: Rubber-to-metal or rubber-to-screen bonding capabilities

Regulatory compliance: FDA, NSF, RoHS, REACH-compliant materials

Scalable production: From low-volume custom runs to high-volume manufacturing

Our custom molded rubber components are trusted by OEMs in food processing, pharmaceuticals, industrial pumps, and beyond.

Conclusion

Custom molded rubber is a cornerstone of precision engineering and industrial performance. From hygienic processing lines to demanding pump systems, the right rubber part can dramatically improve equipment life, system efficiency, and product safety.

Whether you're looking for Tri Clamp sanitary screen gaskets, AODD valve balls, or FDA-grade sanitary gaskets, choosing a trusted manufacturer is crucial.

At California Rubber, we bring decades of experience, top-tier materials, and advanced molding methods to every project. If you’re ready to take your rubber components to the next level, we’re here to help you build the best solution—customized for your performance needs.

Report this page